Summer 2011

Welding Lab Upgrades

| Issues |

Cost

Time

Electrical Power Requirements |

Items

Remove existing smokeeaters, exhaust fans & duct work

Gives additional Headroom, current headroom limits access with forklift and taller items

Clean & Paint the lab

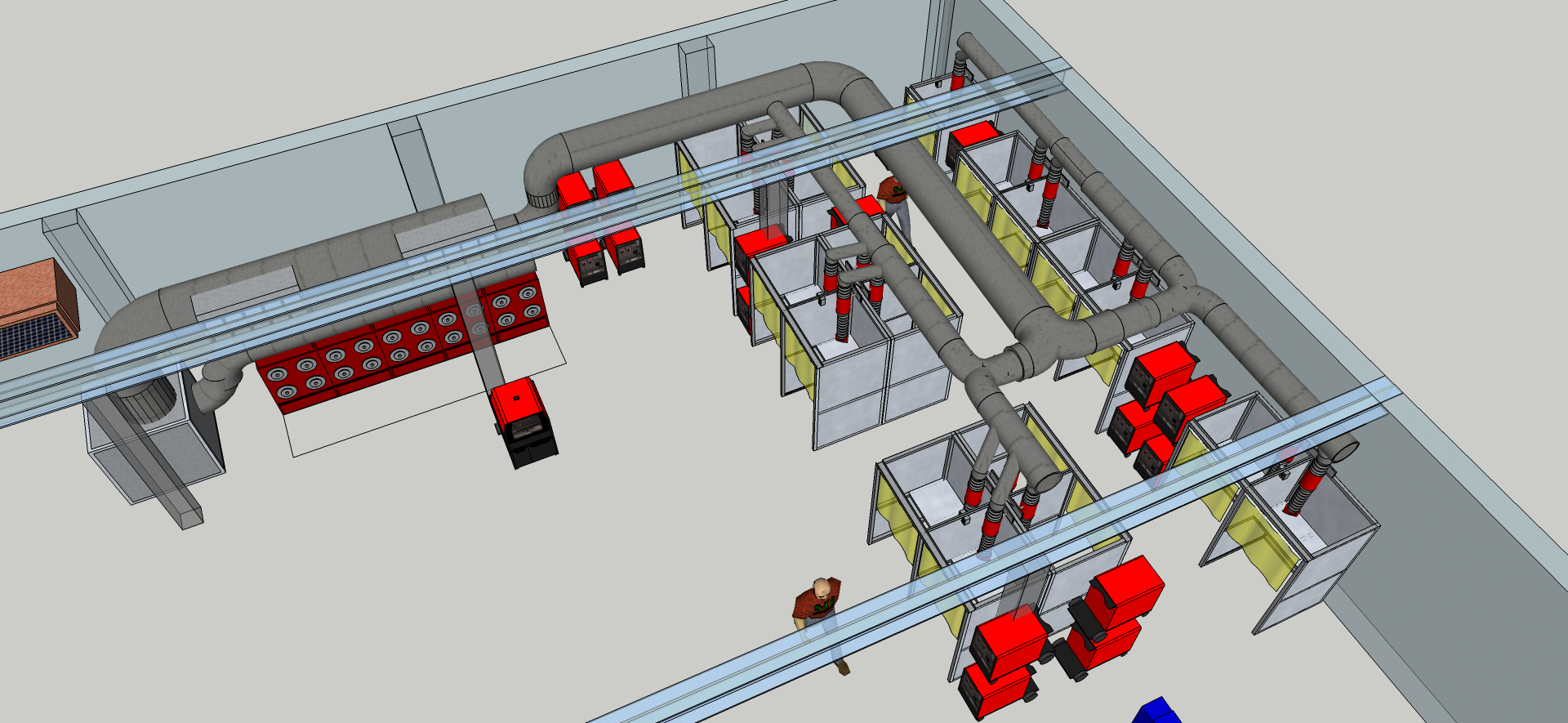

New fume extractors/Collectors

Collection distance from welding surface: 15" - Preferred

"Low Vac System" Centralized system

Installation of fume extractors

New Duct Work for Extractors and Other Exhausts

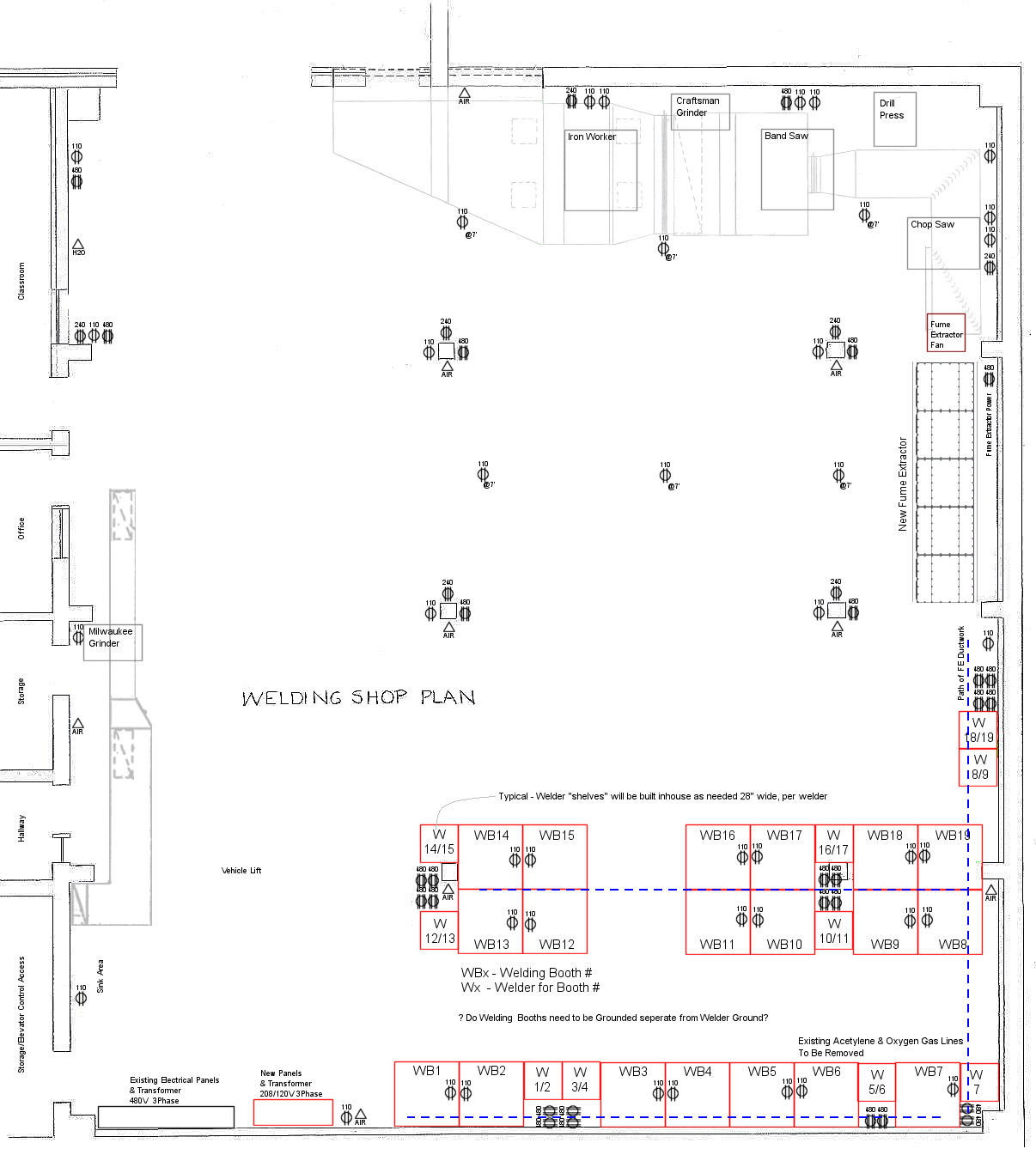

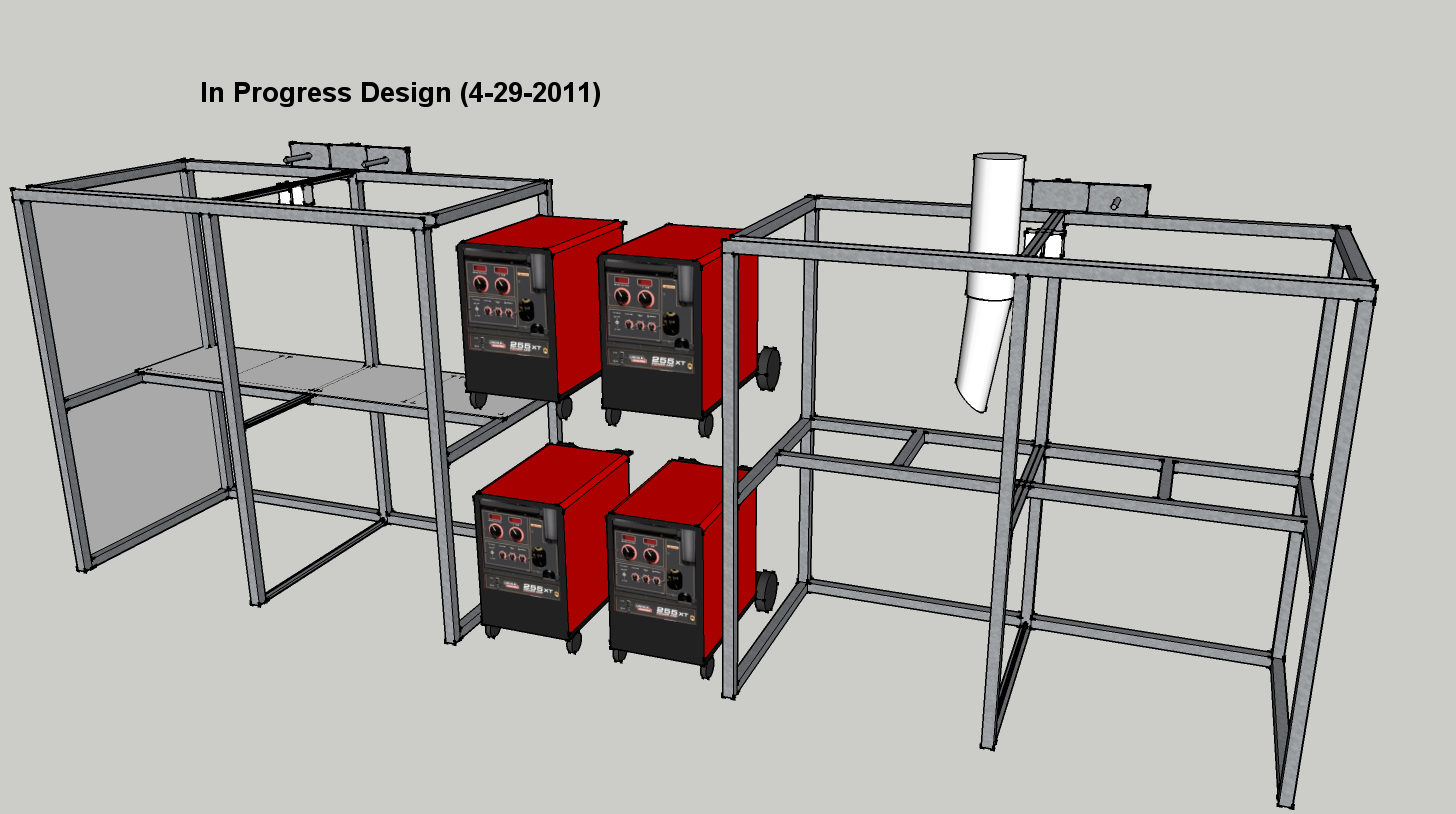

New welding booths

Reorganizes shop layout for more useable floor/work space

Relocate & add electrical power for Welders

Relocate & add electrical power for Fume Extractor

Relocate & add gas lines

Relocate & add air lines (Depending on New Fume Extractor needs)

Rework Metal Former to 460v or 120v

Rework Mechanical - HV, Dampers, Controls, VFD

WBRC Design - Design Electrical/HV

Summit Enviromental - Cleaning Work Plan

Similar Unit:

Lincoln Electric Solution 2

|

| 2 |

|

FilterBank Systems |

| 1 |

M18464-10 |

SF20000RI 22kW Extraction Fan |

| 19 |

|

LTA 2.0 Telescopic Extraction Arms |

| 19 |

K1655-3 |

Lamp w/Arc Sensor Kit |

Lincoln Electric Solution 1 (7/3)

|

| 10 |

K1654-2 |

Statiflex 200M Fume Control Units |

|

20

|

K1655-5 |

LFA 2.0 6.5' Extraction Arms |

| 20 |

K1656-1 |

SF 2400 Fans |

| 20 |

K1669-4 |

Lamp w/Arc Sensor Kit |

|